Cleanroom wipes are the perfect tools for cleaning any surface in a cleanroom, including walls, machinery, fixtures, transport carts, or any other production materials. Cleanroom wipes have been developed to effectively remove contaminants, particles, and any residual material in critical manufacturing & controlled environments.

Effective control in minimizing contamination within any cleanroom environment is critical. Various studies have shown that cleanroom wipes are one of the most important consumables in your critical environment.

How do you choose the right cleanroom wipe?

The main factors to consider when comparing cleanroom wipes for suitability are:

- Physical properties and characteristics

- Edge treatment

- Size

- ESD requirements

- ISO classification of cleanroom

Physical properties & characteristics

The wipes substrate is key to determine factors such as cleanliness, durability, water/solvent absorbency, heat resistance, chemical resistance, particle count and cost.

Pre-wetted wipes

Pre-wetted wipes are an excellent solution for disinfection of surfaces within a cleanroom. One of the main advantages of using pre-wetted wipes is the convenience of not having to manually mix IPA / water solvents. Each wipe contains the exact amount of IPA and DI water saving technicians time on mixing, spraying, or applying the correct amount of liquid to get the job done effectively. These wipes can also be supplied with WFI water. Technicians simply open the bag and pull out a pre-wetted wipe that is ready to be used. Pre-wetted wipes are also available sterilized for high grade cleanroom environments. For applications where the exact amount of IPA is critical, then a pre-wetted wipe should be used instead of manually wetting a dry wipe.

Polyester wipes

Dry knitted or woven wipes are manufactured with a continuous filament, are low in particulates making polyester wipes the cleanest substrate. Polyester wipes are high in durability and strength; this substrate resists abrasion under rigorous use. Our low lint continuous polyester cleanroom wipes are commonly used for wiping sensitive surfaces, research work areas, or finished products and widely used in Class 10 (ISO 4) and Class 100 (ISO 5) cleanrooms. Can be Gamma Irradiated for sterility.

Non-woven wipes

A cellulose and synthetic blended hybrid provide additional absorbency for spill clean-up and removal of thick liquids. Non-woven wipes are commonly used where liquid retention is important. These are one of the most popular cleanroom wipes for general wipe down and spill control in cleanrooms classified at ISO Class 5-6 and above. As well as being one of the most economical wipes, non-woven wipes are low-linting, strong, have chemical resistance properties and low levels of NVR (non-volatile residue).

Edge treatment

Wipe fabric is produced on large rolls and needs to be cut to size. The very action of cutting the fabric can produce unwanted particles so the edge treatments give multiple levels of cleanliness. Choosing the correct finish is critical as this will determine the right application. Wipes that are made from the same fabric, for example “Polyester” but have different edge treatments, can have multiple levels of cleanliness. The most common edge treatments are knife cut and laser cut.

Laser Cut

These wipes are cut using a laser which also seals the edges using heat. The laser seal edge treatment is cleaner than the cold knife cut as the fiber ends are melted, leaving no residues behind. These wipes are ideal to clean sensitive surfaces, biosafety cabinets, fume hoods, and wipe off finished products, equipment and parts. These ultrasonically Sealed Edge wipes are suitable for ISO 3-4 (Class 1-10) and higher.

Knife Cut

The edge of these wipes is cut with a steel blade, which can leave some fibers on the wipe. These wipes are an excellent option to clean surfaces such as table tops, instrumentation, cleaning benches, or research work areas. However, these are not recommended to have direct contact with the final product as there is a risk of release particles which could contaminate the product. These wipes are suitable for ISO 5-6 (Class 100 -1,000) and higher.

Size

9″ X 9″

A 9” x 9” wipe is the most common size for surface and product cleaning. When quarter folding a 9”x9” wipe it will perfectly cover the palm of the hand, making it easy to clean effectively.

12″ X 12″

12” x 12” wipes are commonly used for large surfaces or cleaning large spills. These are also used for cleaning work surfaces, where operators can use a product alongside the wipe to clean a surface.

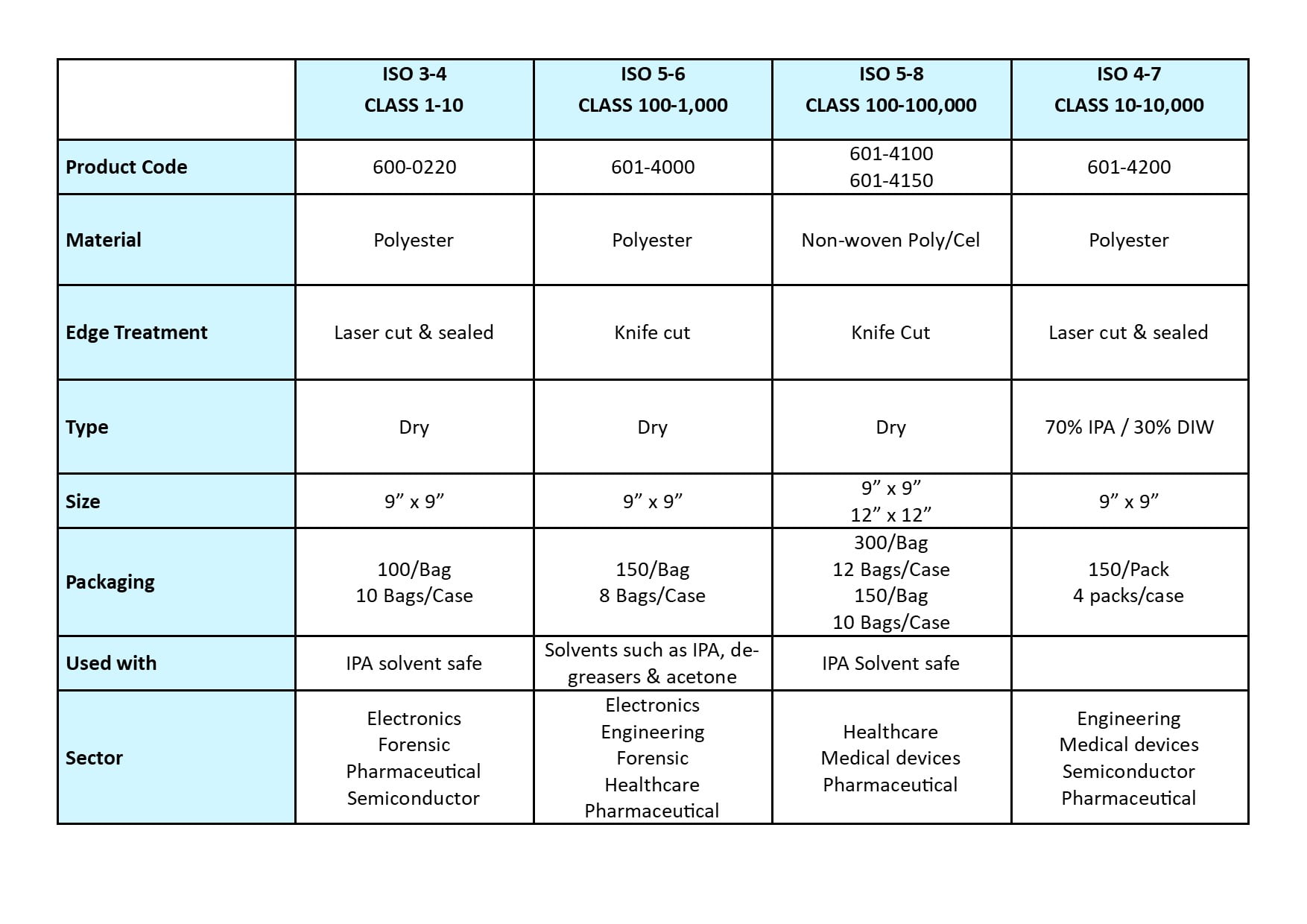

Wipes Specifications

How to Fold Cleanroom Wipes

Folding and using a low-linting wipe in a particular way maximizes efficiency and effectiveness in a controlled environment.

The best technique to clean a surface in your clean room is a wet clean, which usually involves an impregnated wipe and a disinfectant or detergent solution.

The mechanical act of wiping a surface will remove a number of particles from that surface. If the wipe and surface are wet, this will break more of the bonds that hold particles to the surface and allow you to pick up many more particles.

Step 1

Hold the wipe in mid-air. Take the wipe by its edges and fold it in half. The wipe should not be placed on any surface during this folding action.

Step 2

Fold the wipe in half again, creating four cleaning faces – two outside and two inside.

Step 3

Wipe in one direction with slightly overlapping strokes from the cleanest areas to the dirtiest areas, lifting the wipe at the end of each stroke.

Step 4

Each face of the wipe will be used for one straight stroke. Turn the wipe over and make a second stroke.

Step 5

Refold the wipe as shown in step 2 to enclose the two contaminated faces and expose the two clean faces. Repeat step 3 & 4 using the two clean faces.

Step 6

The wipe may be completely unfolded, reversed, and refolded beginning at step 1 to enclose the contaminated faces and expose the four remaining clean faces.

Step 7

Once all 8 sides have been contaminated, dispose of the wipe according to site protocol.

Step 8

Continue with a new clean wipe, following all prior steps until the full surface area is clean.

Our Range

INTEGRITY 9″ X 9″ POLYESTER WIPES, LASER CUT EDGE, 140 GSM

Laser sealed edge ensures ultralow particles, fibers, extractables, and ions

INTEGRITY 9″ X 9″ POLYESTER WIPES, COLD KNIFE EDGE, 125 GSM

Low levels of particulate and extractable counts, resists abrasion under rigorous use

INTEGRITY 9″ X 9″ NON-WOVEN POLYESTER/CELLULOSE WIPES, 68 GSM

Combines the strength of polyester with the absorbency of long cellulose fibers

INTEGRITY 12″ X 12″ NON-WOVEN POLYESTER/CELLULOSE WIPES, 68 GSM

Combines the strength of polyester with the absorbency of long cellulose fibers

INTEGRITY 9″ X 9″ PRE-WETTED WIPES, LASER SEALED, 70% IPA, 30% DI

The pre-wetted wipe solution increases both cleaning efficiency and cleaning protocol consistency

INTEGRITY 9″ X 9″ MICROFIBRE DRY WIPES, 104 GSM

Laser sealed edges ensure ultra low lint and particle levels, good absorbency and wiping efficiency.