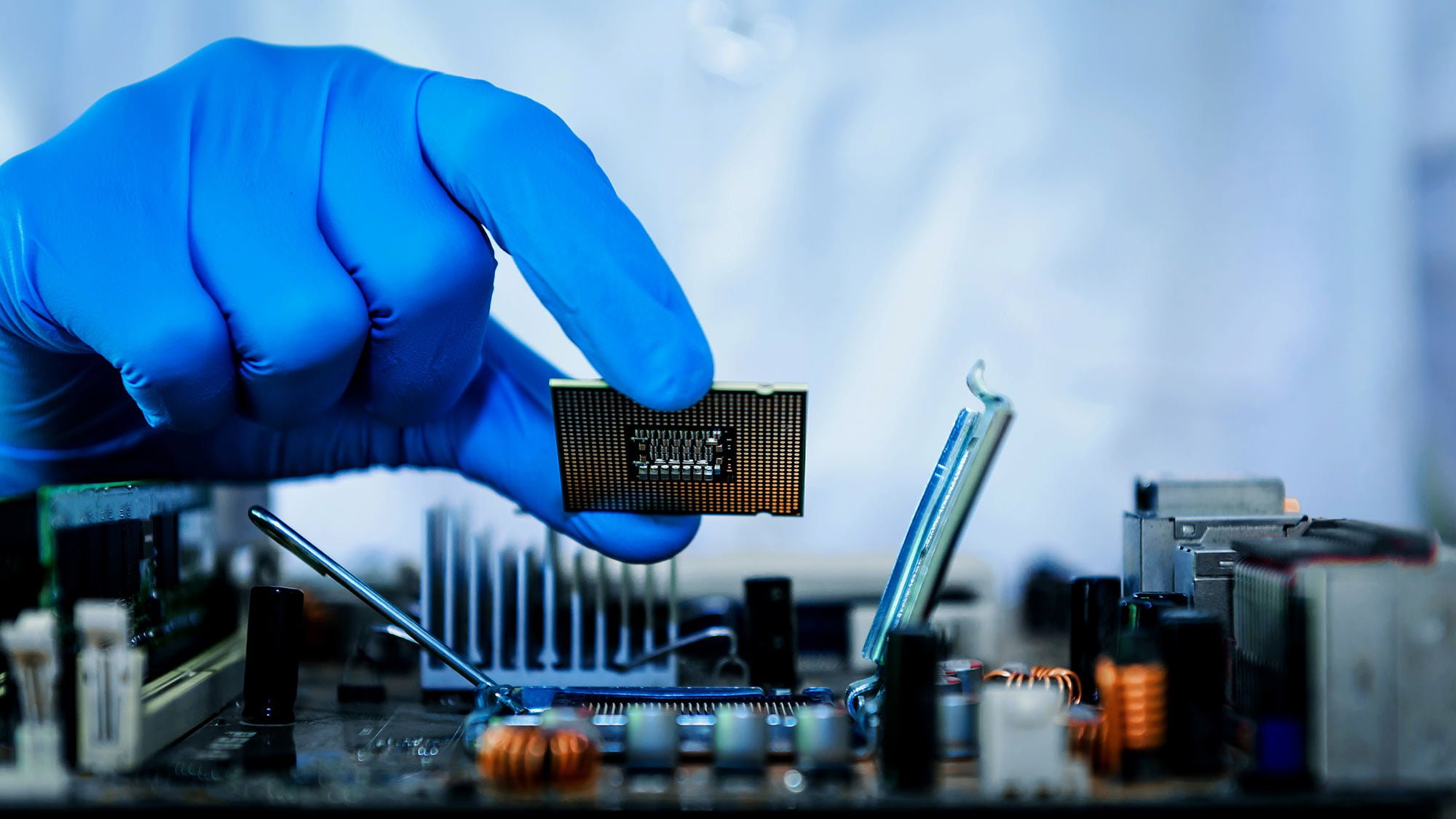

Choosing the correct Cleanroom Gloves benefits both the user and the product. It protects the user from cleaning agents and/or chemicals and protects the products from contamination. Integrity Cleanroom® is here to answer any questions you have about this vital part of any cleanroom operations.

The chemicals used, allergies, glove change frequency, and type of work carried out need to be considered. But are you maximizing your efficiency by using the right glove? Let’s firstly look at the kinds of glove suitable for these critical environments:

Nitrile Cleanroom Gloves

Nitrile Cleanroom Gloves are the most popular choice, offering superior abrasion resistance and excellent biohazard protection. They have good dexterity properties and a micro-roughened finish located on the surface of the glove, which gives a non-slip grip, whether gloves are wet or dry, making them incredibly versatile. Nitrile glove benefits are used across a broad spectrum of industries, although commonly referred to as “Medical Examination Gloves.”

Suitable for a range of scenarios, including:

An alternative solution where latex allergies are a consideration

Protecting people from blood-borne pathogens and other environmental contamination

Medical and dental professionals

Operators in laboratory settings

Working with new adhesives or ink. E.g., tattoo artists and therapists in salons

Shop Nitrile gloves

Latex Gloves

Latex Gloves are durable, flexible and comfortable to wear. They offer higher chemical resistance than synthetic alternatives. As a natural material, biodegradable and environmental qualities are also more sustainable compared to synthetic derivatives.

Their use covers a wide range of applications, including examination, diagnostics, and therapeutic procedures, especially within the medical industry. However, with their high tensile strength and puncture resistance properties, they can also be used in sterile manufacturing environments.

Latex gloves are suitable for a range of tasks, including:

Medical, dental and veterinary settings

Childcare and senior care

Food processing and catering

Hairdressing and cosmetic procedures

Janitorial and sanitation

Automotive

Manufacturing

Crime-solving and forensics

Shop Sterile Gloves

Vinyl Gloves

Vinyl cleanroom gloves are a cost-effective alternative to natural and nitrile materials. The main advantage of these gloves is that they are latex-free and hence do not cause any skin allergies or reactions. It offers standard protection when handling most chemicals. The Integrity® 12 inch, the ambidextrous vinyl glove also features a high level of static resistance, essential when handling static sensitive equipment within ESD protected areas.

Benefits of vinyl gloves include:

Latex-free

A looser fit, so are easy to don

An economic option

Suitable for short-term, low-risk use

Have anti-static properties

Are ideal for use with non-hazardous materials

Shop Vinyl gloves

Heat-Resistant Gloves

The amount of heat protection required is subjective to the working conditions. Operating industrial heating equipment, working close to high-temperature material, or working with hot components, requires correct hand protection to ensure user safety and maintain critical standards.

Some of the advantages of heat-resistant gloves are:

Liquid-proof design, ideal for wave solder operations

Designed for a wide range of temperatures, in both wet and dry environments

The material resists solvents, fluxes, abrasions, and cuts

Non-shedding

Cleanroom packaged in ESD-safe packaging for immediate use

Shop heat-resistant gloves

Nylon Glove Liners

Nylon glove liners reduce perspiration and minimize skin irritation caused by frequent gloving, especially with gloves manufactured from materials such as latex and PVC. Glove liners are, therefore, a great benefit to all users, but essential for those with sensitive skin. Liners consists of seamless construction to increase comfort, are reusable, and are ambidextrous. Integrity glove liners are ideal for use in controlled environments, laboratories, and manufacturing environments.

Shop nylon glove liners

Glove packing in Cleanroom Environments

Depending on the Classification of the Cleanroom, it can be an important consideration of what glove packaging to use within the Cleanroom Environment; this topic can often be overlooked. Conventional cardboard packaging may be appropriate in a general medical or dental setting, but not permitted in Cleanrooms. Within a cleanroom setting, particulate control is as vital as sterility, and – as cardboard releases particles – it is best left out of the Cleanroom Environment.

If gloves are taken into a Cleanroom Environment and packaged in cardboard dispensers, they should be decanted in a suitable prep area, and placed into cleanroom polybags. Then they should be taken into the cleanroom and placed into the glove dispenser.

Additionally:

Disposable cleanroom gloves should be packed in cleanroom polybags, which are manufactured in a clean environment, and are cleaned before entering the cleanroom.

Sterile cleanroom gloves should be packed in individual pairs in non-particulate materials such as a polyethylene wrapper within a cleanroom outer pouch. This packaging is also manufactured in a cleanroom for ultimate guarantees of cleanliness.