Students, industry leaders, and Professors at Dublin University are currently building, designing and preparing to launch Ireland’s very first satellite.

The satellite will be able to carry three experiments around Low Earth Orbit at an altitude of 248 miles.

Gamma-ray Module;

The Gamma-ray Module (GMOD) is a miniaturized sensor that is able to detect gamma-rays from cosmic and atmospheric phenomena.

ENBIO Module;

The ENBIO Module (EMOD) is an experiment measuring how protective coatings perform in space. EMOD consists of two black panels and two white panels, with their temperature constantly monitored.

In orbit, within the shade, temperatures can fall to below freezing (-212°F); however, indirect sunlight can get extremely hot (302°F), and these changes in temperature can cause problems for the spacecraft. ENBIO coatings control the temperature of the spacecraft. The Solar-Black is highly absorbing and highly emitting; Solar-White is low absorbing but also highly emitting.

Wave Based Control Module;

The Wave Based Control Module (WBC) is an attitude control system. A spacecraft’s “attitude” is its orientation of space. The satellite will use Earth’s magnetic field to turn itself in any direction.

With completion and launch expected within the coming years, the team will continue to utilize the Cleanroom for future projects and educational purposes, supporting Dublin University students to build small satellites across the university’s Space Science programs.

Main Objectives

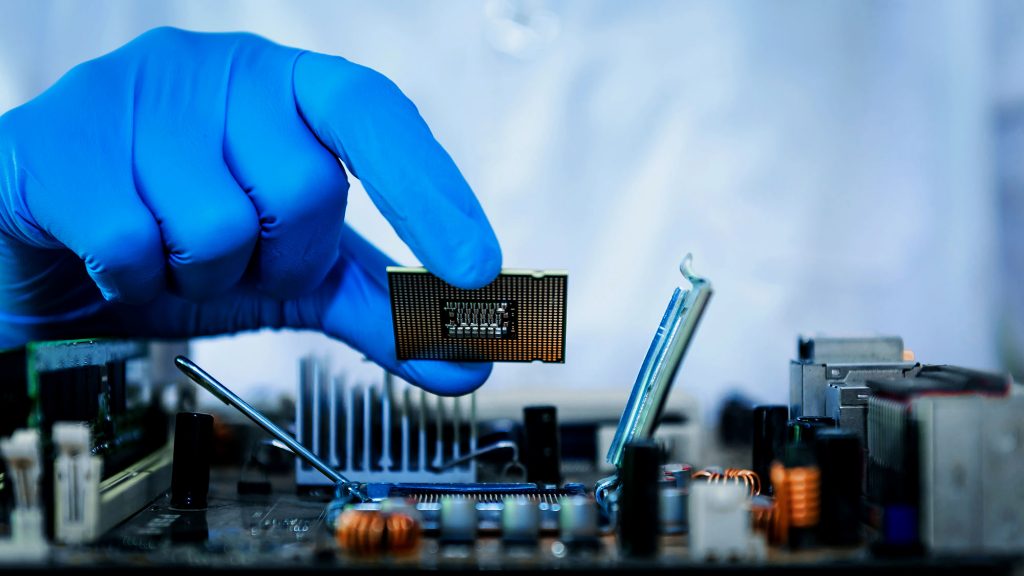

A PhD student in the University’s Space Science group, who works as Assembly Integration and Testing Technician, approached Integrity Cleanroom in 2018. He searched for a solution to guarantee a highly clean environment in which the University Students could design, assemble, and test the 7in x 4in x 4in satellite’s three payload experiments and subsystems.

The Solution

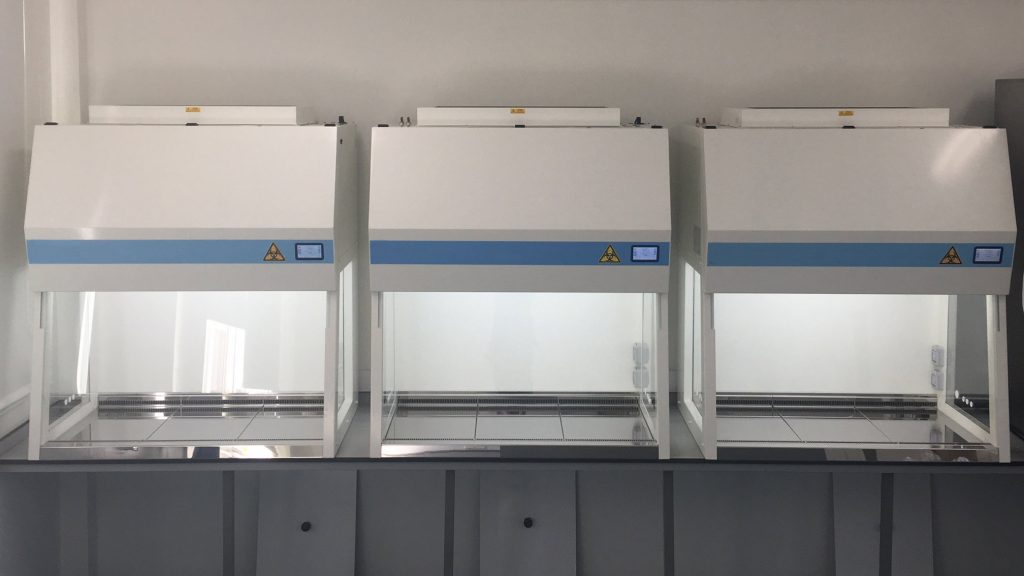

10ft x 10ft ISO Class 8 Modular Cleanroom.

The experienced team identified ISO Class 8 Modular Cleanroom as the solution to meet the needs of this project, therefore being able to assemble sensitive technologies and be capable of withstanding the severe environment of space.

The unit includes a 10ft x 10ft Production Area, with Soft-Close Sliding Doors and LED Lighting.

The high-quality system, assembled on-site, is exceptionally adaptable, constructed from a smooth profile aluminum framework with aluminum composite and clear non-break polycarbonate created windowpanes.

The room also includes the CAM1000 Clean Air Module, guaranteeing a positive pressure and ISO Class 8 clean environment within the production area. The unit filters the air as it enters the room through HEPA filters (99.997% efficient at 0.3 microns) before creating the positive pressure in the environment, providing up to 1000m3of HEPA filtered air, a total of 75 clean air changes per hour.